I sent an email to CAMCO a number of months ago that I feel like a machinist again! You don’t feel like you’re being wrestled by a CAM system. It’s not driving you, you’re driving it.

Students who are curious about a path forward to manufacturing technology will find an enthusiastic mentor at Northern Maine Community College (NMCC). Instructor Dean Duplessis has refined their curriculum to equip students with technical know-how in CNC milling and turning in under a year. Combining hands-on experience, longhand coding and CNC programming for both technologies is a full load, but Duplessis has found an easy-to-learn CAM software in GibbsCAM that students can understand and use almost immediately.

Duplessis knows machining, having worked in private industry after graduating from a very similar program. He has led the CNC program since its launch over 15 years ago. Northern Maine Community College (NMCC), located on the former Air Force Base in Presque Isle, attracts the interest of both students and businesses.

Originally a 2-year program that included manual machining, the program now focuses strictly on programming CNC machines both longhand and using GibbsCAM. The result? Students can earn certification within 9 months with a skillset that attracts employers.

Duplessis comments, “It’s a 100% employment rate. We have students that are going out and interviewing between their two semesters of instruction. They have a better insight in terms of the environment in which they see themselves. And by graduation, if they haven’t already accepted a position, then they’re in the process of doing so.” The shorter program length also helps attract faraway students that need to pay for housing and want fast results and earning potential.

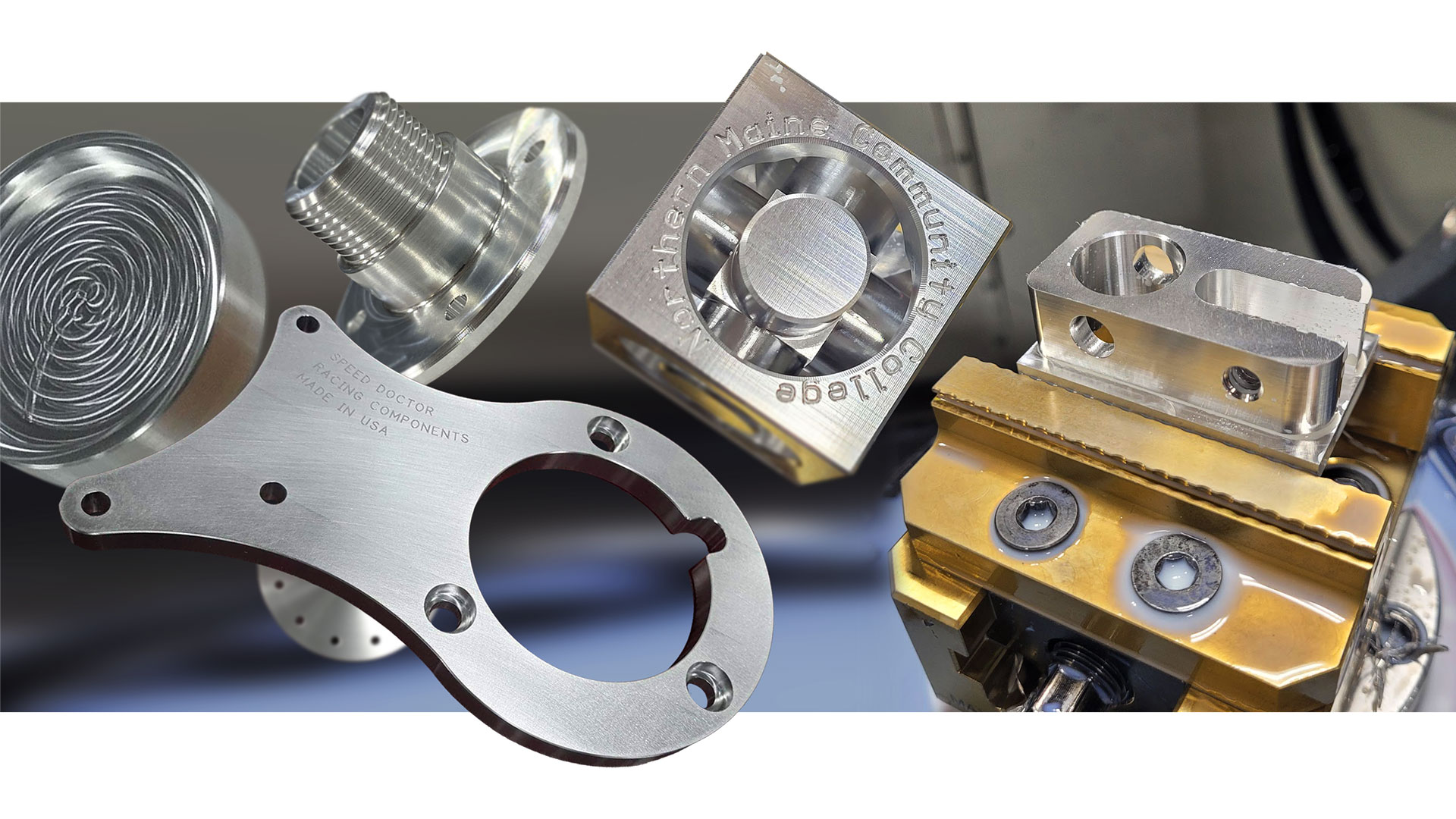

The coursework teaches more than CAM concepts. Students also learn about manufacturing for the real world. Duplessis explains, “We’re unique in our philosophy that if you’re going to provide instruction, you need to simulate the real world as much as possible. We run a full-fledged non-revenue generating job shop. The students are making and shipping parts all over the country.”

Customers include automotive aftermarket, recreational vehicles, coal mining, and even the consumer market. Customers are responsible for raw materials, coating, anodizing, and outside expenses. In exchange, the students get a better learning experience.

During the first semester, students work on the basic concepts of CNC, learning longhand programming using g-code and m-code, and how CNC machines work. By the second semester, they start to see what they can create using GibbsCAM software. “In the first four-hour class students are developing code, so they’re very excited about it. I mean, their feedback is exactly that, ‘Dean, this is easy to use. It makes sense.’ Software can be a challenge to learn, but with GibbsCAM, it was very seamless.”

It hasn’t always been this way. After trying other CAM software for many years, the college was looking for a CAM system that was “very user-friendly with a shallow learning curve.” Says Duplessis, “That’s how we got on board with GibbsCAM. I don’t want to take away anything from anybody, but we needed something where a student could feel productive really early in the courses.”

We run a full-fledged non-revenue generating job shop. The students are making and shipping parts all over the country.

Their previous CAM software programs required a lot of setup procedures such specifying tool libraries before any programming could be done. In addition, basic tasks like importing a 3D object were “extremely cumbersome.” “We were spending a lot of time just getting through the mechanics. ‘You always need to do this, you always need to do that.’

Duplessis found that with GibbsCAM, the processes and the functionality were stable, repeatable, and doable, allowing students a faster pace for learning and applying. Dean explains, “We needed something that was going to get the student’s buy-in early on. They recognize they need to understand g and m code so they can look through the code and spot an input error. But the ease with GibbsCAM, they recognize how to make the change, where to make the change and the simplicity with making the change. He adds, “I sent an email to CAMCO a number of months ago, that I feel like a machinist again! You don’t feel like you’re being wrestled by a CAM system. It’s not driving you, you’re driving it.”

Duplessis was amazed to discover enough time in his classes to introduce 4- and 5-axis programming within a short time. “We’re offering GibbsCAM in both a two-credit mill course and a two-credit lathe course. Students are earning four college credits while learning CAM programming. And as I started dabbling with it, it’s like, this is the perfect vehicle to get these students introduced to fourth and fifth axis.”

Duplessis starts with machining in a wireframe environment, leaving it optional to use the geometry pallet until a few weeks into the semester. That’s when he introduces importing and extracting features from solid models using SolidWorks. Eventually he will give them a dimensional drawing and let the student choose how he wants to proceed. As he points out, “there is more than one way to be successful.”

In addition to using GibbsCAM, the classes use Renishaw probes, using GibbsCAM to point to subprograms. NMCC is also a Haas technical education center, offering training exclusively on Haas mills and Haas lathes. As a CAM system, Duplessis is not only pleased with GibbsCAM software but he is also very pleased with the support and technical expertise he receives from the regional GibbsCAM reseller CAMCO.

While the staff at NMCC were fearful of being second place to industrial customers, they quickly found a receptive partner in CAMCO. Duplessis quickly comments, “I can’t say enough good about the technical support that we’ve had from those folks. And the nice thing is, while it hasn’t always been the same individual, it’s a consistent theme of knowledge of the product. To be able to throw a curveball… whether it’s a new coordinate system or new work group or a timeframe on a post repair… I can’t say enough.”

Duplessis says, “It was critical that this be an education-friendly experience. And not just the software, not just support, but all the other resources as well.” With GibbsCAM’s online footprint of videos and training materials, he has found that NMCC students can access more educational content for GibbsCAM than many other software programs. “A student can go to the internet and look for a YouTube video on maybe a peck drilling cycle or a reaming cycle or something, and I’ll say 90% of the time there’s content about it. We’re looking forward to a long-term relationship, not only with our local distributor, but GibbsCAM as well.”

I can’t say enough good about the technical support that we’ve had from those folks. To be able to throw a curveball… whether it’s a new coordinate system or new work group or a timeframe on a post repair… I can’t say enough.

Wilson Tool International enhances custom part production efficiency through GibbsCAM automation, utilizing macros for rapid programming and standardized processes across its diverse manufacturing sites.

Wallåkra Mekaniska leverages smart manufacturing and AI tools like GibbsCAM and Up2Parts to streamline operations, improve efficiency, and enhance sustainability through reduced energy consumption and optimized processes.

Capristo Automotive has set itself the goal of enhancing luxury sports cars with high-quality accessories and making them even more unique. GibbsCAM was brought on board when the CAM programming of an INDEX G400 YB could not be managed with the existing CAM software.

Northern Maine Community College (NMCC) has implemented a curriculum that equips students with CNC programming skills using GibbsCAM software, allowing students to earn certification within 9 months and achieve a 100% employment rate.

MUT-Tschamber, a mechanical engineering company in Germany, has implemented Sandvik Coromant's PrimeTurning™ technology and GibbsCAM NC programming solution to achieve higher throughput and productivity.

Toolmaker Rieco System Srl achieves greater machining precision and optimized production time with the help of GibbsCAM software.